In the world of DTF (Direct to Film) printing, one key decision can dramatically affect your workflow and final results: choosing hot peel or cold peel transfers.

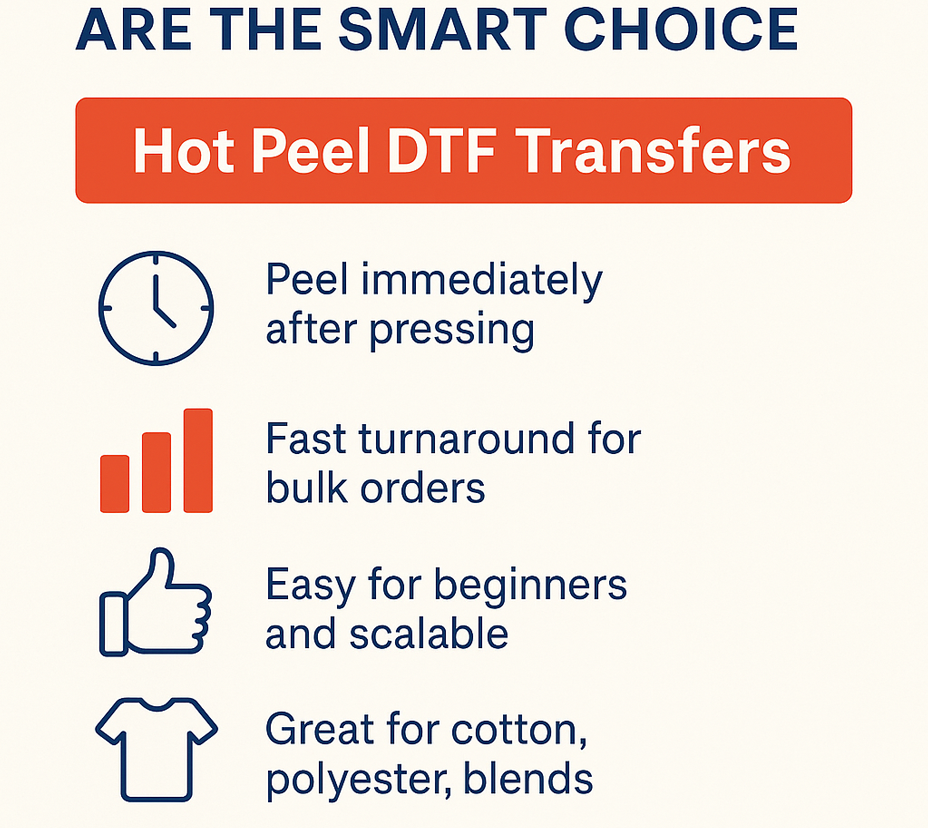

At DTF West Coast, we specialize in Hot Peel DTF Transfers—and for good reason. Hot peel isn’t just faster—it’s efficient, reliable, and perfect for today’s high-demand printing environments.

Here’s why hot peel stands out as the go-to method for professionals.

1. Speed and Efficiency: Hot Peel Leads the Way

Hot peel transfers are ready to peel immediately after pressing, while still warm. That means:

-

No need to wait for cooling

-

Peel in just 5–10 seconds

-

Ideal for bulk orders and fast-paced production

-

Perfect for on-demand custom printing

With hot peel, you can move from press to finished product in seconds—keeping your turnaround times fast and your customers happy.

2. Easy for Beginners, Scalable for Businesses

If you're just getting started with DTF printing, hot peel is the easiest way to hit the ground running. It requires fewer steps, less handling, and no extra cooling equipment.

And as your business grows, hot peel scales with you—allowing for high-volume production without slowing down.

3. Great Results with the Right Materials

Hot peel works beautifully with common apparel materials like:

-

Cotton

-

Polyester

-

Cotton/poly blends

Whether you're creating event shirts, custom merch, or fashion-forward pieces, hot peel delivers bright, clean prints on lightweight fabrics with a soft hand feel.

4. Quality and Vibrancy That Hold Up

While cold peel may offer slightly crisper edges for extremely detailed designs, hot peel transfers still provide excellent vibrancy and durability, especially when properly applied.

With hot peel, you get:

-

Smooth, lightweight finish

-

Bright colors that pop

-

Solid resistance to regular washing (when cured correctly)

It’s the ideal balance of speed and quality for most applications.

5. Cold Peel: When to Consider It

Cold peel transfers do have a place—for example, if you’re working with:

-

Dark or textured fabrics

-

High-resolution photo prints

-

Projects that demand ultra-fine detail

However, these jobs often require more time, handling, and equipment like cooling fans or trays.

At DTF West Coast, we prioritize speed, simplicity, and outstanding print quality—which is why we focus on Hot Peel DTF Transfers for most customer needs.

6. Why Professionals Choose Hot Peel

Print shops and creators choose hot peel because it lets them:

-

Complete more jobs per day

-

Reduce production time

-

Avoid errors from over- or under-cooling

-

Deliver fast, clean results with minimal effort

It’s the smartest choice for efficient, everyday printing.

Final Thoughts

If you're looking to produce beautiful, long-lasting prints quickly and efficiently, Hot Peel DTF Transfers from DTF West Coast are the way to go. We’ve optimized our products and process to make sure you get fast results without sacrificing quality.

Whether you’re running a high-volume shop or just starting out, we’re here to help you print better—and faster.

FAQs

1. What is Hot Peel DTF?

Hot peel DTF involves peeling the film while it's still warm, right after pressing. It saves time and simplifies the workflow.

2. Is Hot Peel good for beginners?

Absolutely! It’s easy to learn and perfect for fast-paced jobs.

3. Does Hot Peel last as long as Cold Peel?

Yes—with proper heat, pressure, and curing, hot peel prints can be very durable and vibrant.

4. What materials work best with Hot Peel?

Cotton, polyester, and blends all work great. It’s especially ideal for t-shirts, hoodies, and everyday apparel.

5. Can I use Hot Peel for bulk orders?

Definitely. Hot peel is designed for speed and efficiency—perfect for large runs and quick delivery.

Share:

How to Build a Brand Around Your DTF Printing Business

Eco-Friendly DTF Printing: What You Need to Know